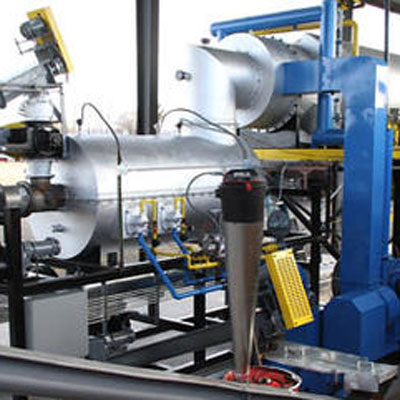

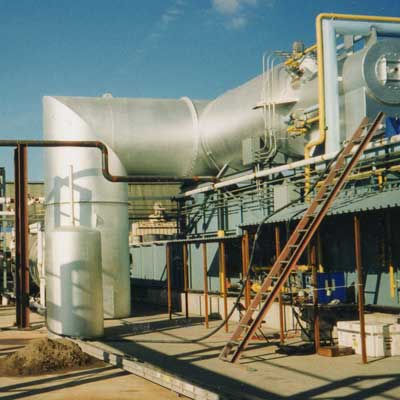

Led by the father and son team of Frank and Jim Reed, R&R Technologies, Inc. (R&R) has over 40 years of experience in the industries of Drum Recycling Furnaces, Pyrolysis (Thermal Conversion), Air Pollution Control Equipment, Waste Heat Boilers and Co-generation. R&R holds intellectual rights for their Drum Recycling Furnaces and multiple Pyrolysis systems. Frank Reed is also published in documentation by Air Pollution Management district and is the recognized expert on Drum Reconditioning Furnaces and Waste Heat Recovery.

Our Environmental Services

We work closely with our clients to determine the best possible solution for each situation providing an array of services.

- Drum Furnaces

- Pyrolysis systems

- Air Quality Systems

- Automated drum reclamation furnace

- Activated Carbon Regeneration

- Waste Management Systems

- Biomass/Tires/MSW to Energy

- Project Consultation